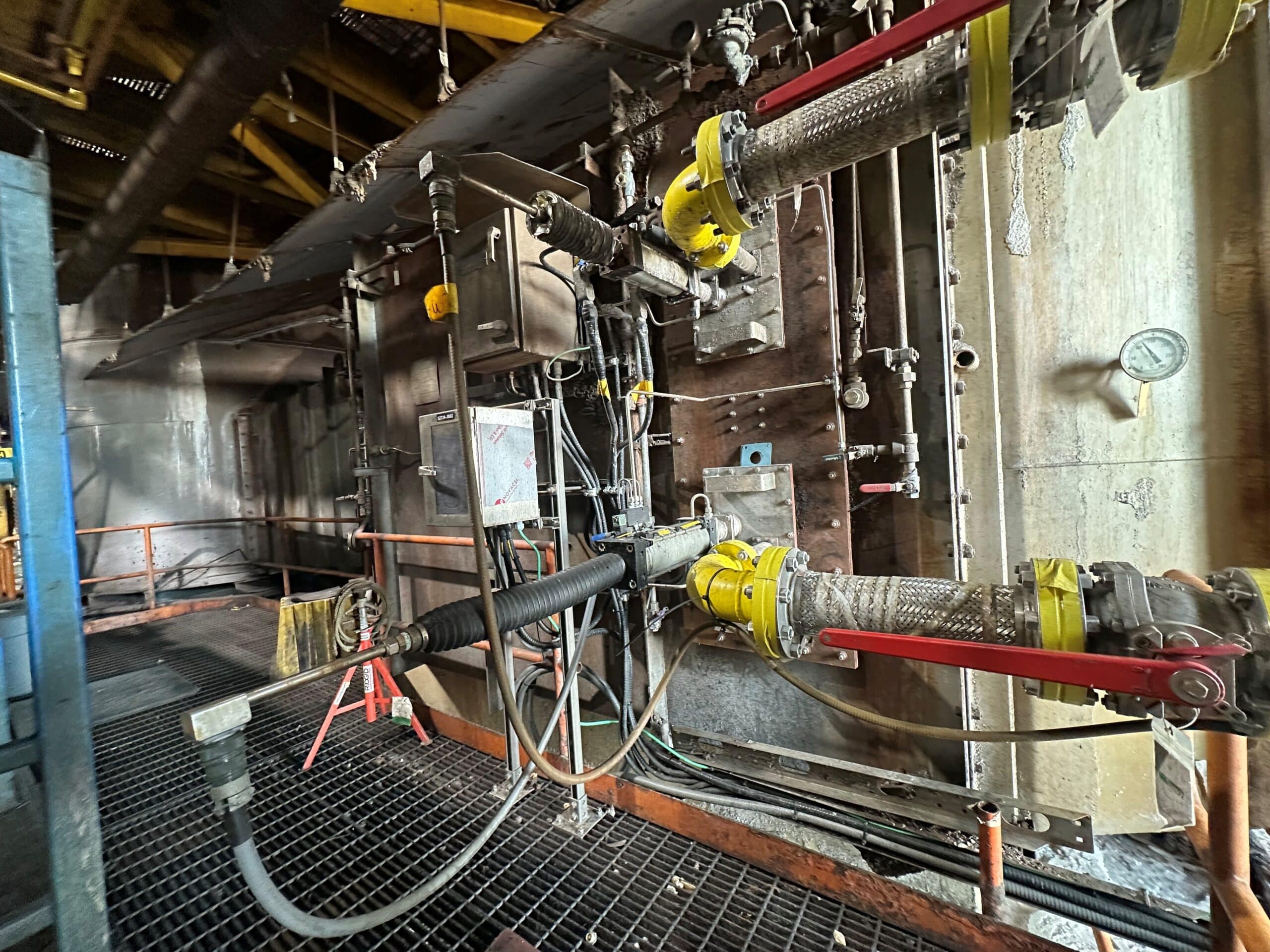

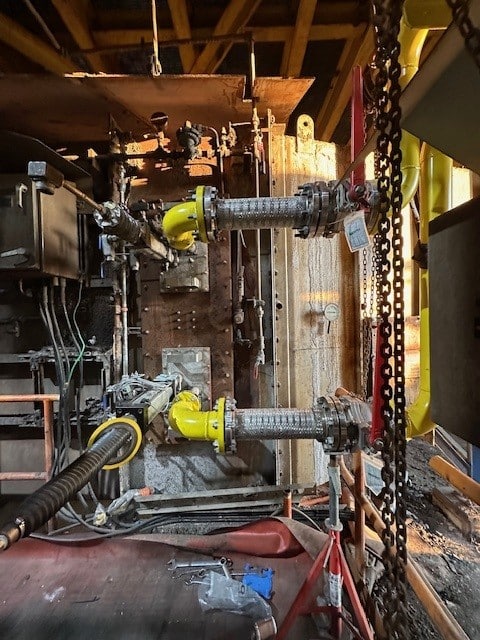

40017 Dryer Modifications

SEC was contracted to complete the 40017 Dryer Modifications for a long term client. The Scope consisted of interior modifications to the refractory, replacing a section of the ducting system, replacing the Exhaust and Combustion fans motors and internal components, installation of a new cyclone, rotary valve and screw conveyor. An additional burner was also installed along with new fuel train and interconnecting piping. The goal of the system changes is to increase the drying capacity of the vessel to meet the newly implemented process circuits product outputs, while optimizing the airflow path, enhancing air circulation, and ensuring efficient removal of impurities and particulates.

SEC successfully completed the project under budget and on schedule with no injuries.