Explore a selection of some of our recently completed work, spanning a wide range of services provided

Project Portfolio

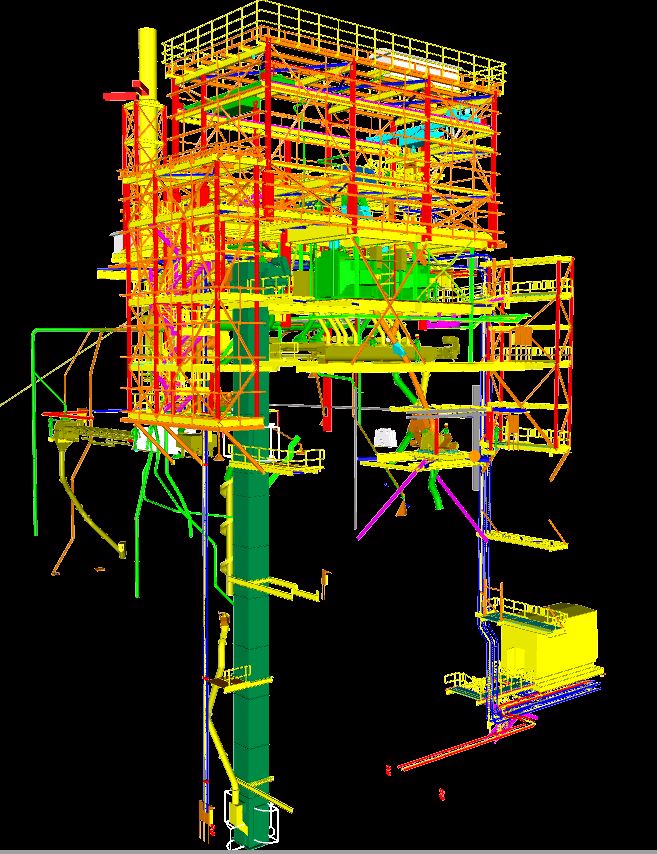

Loadout Screening Upgrade

Industries: Mining

In 2019, SEC completed an eight month product loadout area de-bottlenecking project which included demolition / modification of existing structure, structural steel modules, heavy lifts, screening upgrades, multiple conveyor upgrades, bucket elevator installation, dust collection systems, new E-house, E&I systems, storage bin modifications, screw conveyor replacements, duct & chute-work upgrades, sclair lines & traced oil piping. Included in this work was the upgrade of 10 conveyors through the loadout and mill areas. This brownfield upgrade project was finished on-time during the customers annual summer maintenance outage. Peak manpower was 210 personnel